GRET OPERATES ON ' DONATIONS & GRANTS ONLY ' ! Serving The Charitable Class

Global Renewable Energy Technologies, Inc.

" Converting Waste To Energy .......

Now You're In The Solution " ! (tm)

Mission Statement:

Our mission is to take full advantage of the technology that has enhanced the capabilities of helping our fellow man enjoy life longer, safer, and reassured that future generations would be able to say… " the same " !

[ WE ] don't answer to profit... nor to the ' BIG ' "profit machine "!

[ WE ] REINVEST TO EXPAND OUR SERVICES TO THE PUBLIC, AND

[ WE ] DONATE OUR PROFIT TO " WORTHY CAUSES AND CHARITABLE ORGANIZATIONS "... AND BECAUSE IT'S THE RIGHT THING TO DO ...

[ WE ] ... DO THE RIGHT THING !!

THE GRET, INC. ' WASTE - TO - ENERGY FACTORY ' (sm)

' The Foremost Recycling & Waste Mgmt. System '...

II. Company Overview & Structure

§ Global Renewable Energy Technologies, Inc. was established on December 20th, 2019.

§ Legal Structure - A (Non-profit ) Waste To Energy Corporation

California ' C ' Corporation # 4543088

EIN 84-4280249

§ Headquartered & located at 68390 Durango Rd.,

Cathedral City, California 92234 - 3698

§ Founders and Voting Members

• Michael A. Castro [ Executive Director - Operations ]

• John Apoian [ Director - Operations Logistics ]

• Patrick ( Rick ) L. Taylor [ Director - Business & Development ]

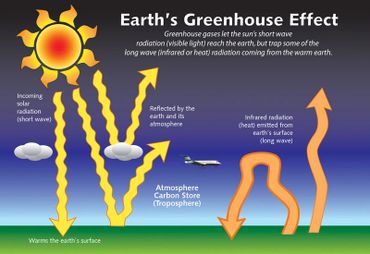

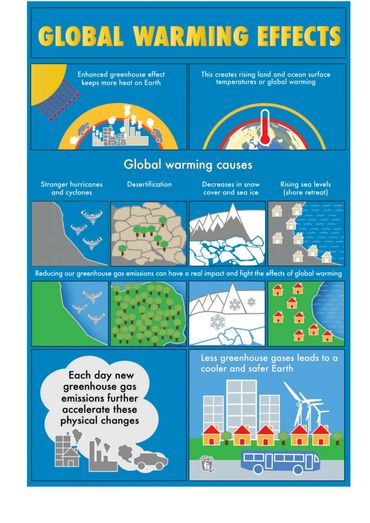

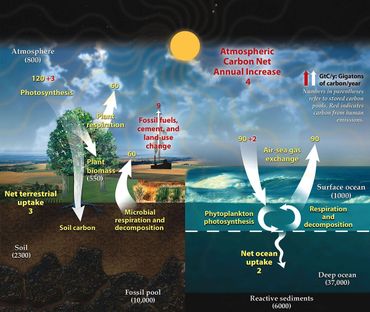

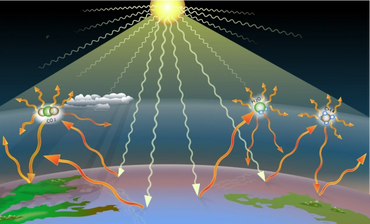

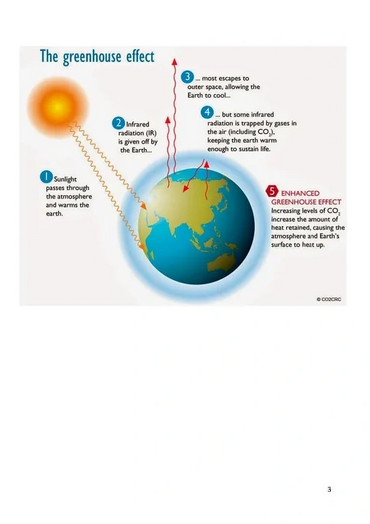

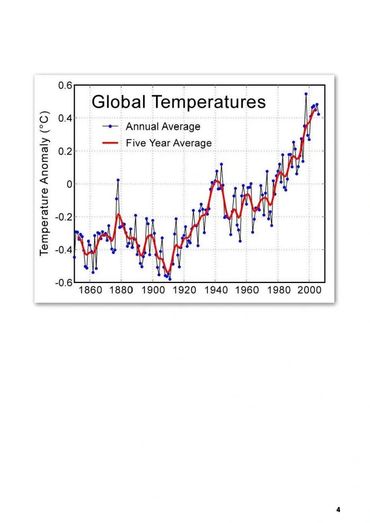

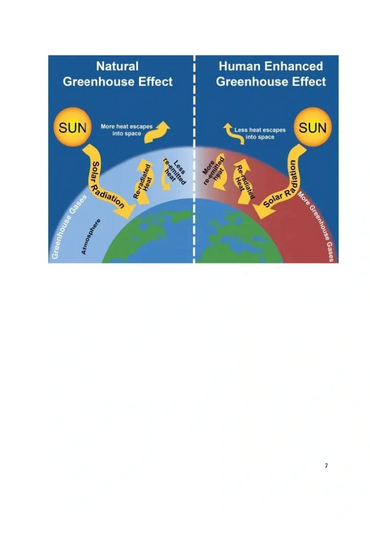

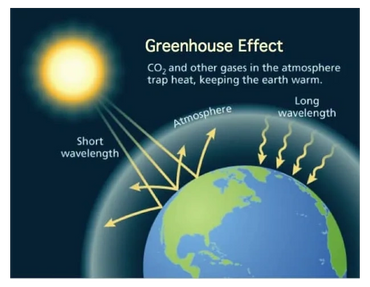

GRET, Inc., a non-profit corporation established on December 20th, 2019 - to serve the public - has a staff of only dedicated people who have committed themselves to saving the planet by combating

( GHG ) - Greenhouse Gas Emissions are exacerbating the daily creation of Global Warming at an ' alarming rate '! [ We ] must

' confront the crisis... head-on ' !

We will do all that [ we ] can possibly do to help reverse this dangerous trend, and we implore you, your family, and your friends to join GRET, Inc., donate or campaign to reverse Global Warming, and commit to helping save the planet for generations to come! It's the [ only ] way to help reverse ' Global Warming ' !

REMEMBER, YOUR DONATION GOES A ' LONG, LONG WAY ' !!

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=7YE7K5NL2M4R4&source=url

GoFundMe ( GRET. Inc. ) Donations

Environmentally Concerned & Grateful

Rick L. Taylor, Director

Business Research Development

" THE EXECUTIVE TEAM "

• Michael A. Castro

Co-founder, Voting Member & Managing Director -

Operations Management

• John Apoian

Co-founder, Voting Member & Managing Director -

Operations Logistics

• Patrick ( Rick ) L. Taylor

Co-founder, Voting Member & Managing Director -

Business Development -Public Relations Liaison

• Katherine ( Kat ) Castro, Director - Legal Adviser & Secretary

• Joe Velasquez, Director - Business Administration Liaison

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

YOUR ' NOT-FOR-PROFIT ' WASTE TO ENERGY SPECIALISTS SOURCE !

EXCLUSIVELY SERVING THE ' CHARITABLE CLASS ' !

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR NOT-FOR-PROFIT WASTE-TO-ENERGY SPECIALISTS SOURCE ' ...

' SERVING THE ENVIRONMENT & HUMANITY ' !

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

WHAT IS PLASMA ARC GASIFICATION?

Plasma Arc Gasification is a high-temperature Pyrolysis process whereby the organics of waste solids (carbon-based materials) are converted into Syngas and

inorganic materials and minerals of the waste solids produce a rocklike glassy byproduct called vitrified slag. An electric arc creates a high temperature during the process in a torch whereby gas is converted into plasma.

The process contains a reactor with a plasma torch processing organics of

waste solids (carbon-based materials) is called Plasma Arc Gasification.

The plasma arc gasification reactor is operated between 7,200F and 12,600F.

The inorganic minerals of the waste solids (MSW) produce a rocklike by-product.

Since operating conditions are very high (7,200F - 12,600F), these minerals are converted into vitrified slag typically comprised of metals and silica glass.

This vitrified slag is basically none leaching and exceeds EPA standards.

Metals can be recovered from the slag and the slag can be used to produce other by-products such as rock wool, floor tiles, roof tiles, insulation, and landscaping

blocks, to mention a few. The vitrified slag, being environmentally acceptable as a recyclable by-product, is one of the more positive attributes of the plasma arc

gasification process for managing MSW.

Our population is still growing and we are producing more garbage, even with the recycling efforts in entire operation. We have come to the “place in time” where GREEN TECHNOLOGY can help “protect human health and

welfare,” and thus the environment, by creating an infrastructure design that will build a sustainable MSW disposing process that can turn our WASTE PROBLEM into useful GREEN ENERGY …….for a safer and better world.

Current Thermal Process Technology(s)

Plasma Arc Gasification 7,200-12,600 F

Conventional Gasification 1,400-2,800 F

Pyrolysis Gasification 1,400-2,800 F

Pyrolysis 1,200–2,200 F

Mass burn incineration 1,000-2,200 F

The Plasma Arc gasification reactor is operated between 7,200F and 12,600F.

The inorganic minerals of the waste solids (MSW) produce a rocklike by-product.

Since operating conditions are very high (7,200F - 12,600F), these minerals are converted into vitrified slag typically comprised of metals and silica glass.

Unlimited Industry Growth & Unlimited Market Span:

1. Number of nations who might be interested in purchasing our products and/or services each year is unlimited worldwide.

2. Amount these nations might be willing to contribute to our products and/or services is unlimited.

3. Our relevant market span is unlimited.

Customer Analysis

Below is a description of who our target customers are, and their core needs.

Unlimited Worldwide Distribution.

Competitive Analysis:

The following is an overview of Global Renewable Energy Technologies, Inc's competitor technologies. Economic analysis with these parameters allows computation of the net revenue (before taxes) of each thermal process:

Type of Thermal Process Technology Net Energy Production to Grid...

Mass incineration =

544 kWh/ton MSW

Pyrolysis =

571 kWh/ton MSW

Pyrolysis/gasification =

685 kWh/ton MSW

gasification =

685 kWh/ton MSW

“Plasma Arc Gasification” =

816 kWh/ton MSW

The vitrified slag produced is basically none leaching and exceeds EPA standards.

Metals can be recovered from the slag and the slag can be used to produce other by-products such as rock wool, floor tiles, roof tiles, insulation, and landscaping blocks, to mention a few. The vitrified slag, being environmentally acceptable as a recyclable by-product, is one of the more positive attributes of the Plasma Arc gasification process for the management of MSW.

Our population is still growing and we are producing more garbage, even with the recycling efforts in full operation. We have come to the “place in time” where the momentum of GREEN TECHNOLOGY can help “ protect human health and welfare,” and thus the environment, by creating an infrastructure design that will build a sustainable MSW disposing process that can turn our WASTE PROBLEM into useful GREEN ENERGY …….for a safer and better world.

Current Thermal Process Technology(s)

Plasma Arc Gasification @

7,200-12,600F

Conventional Gasification @

1,400-2,800 F

Pyrolysis Gasification @

1,400-2,800 F

Pyrolysis @

1,200–2,200 F

Mass Burn Incineration @

1,000-2,200 F

HELP SAVE THE ENVIRONMENT... AND

REVERSE ' GLOBAL WARMING '...

DONATE TODAY,... WHATEVER YOU CAN!

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=7YE7K5NL2M4R4&source=url

GoFundMe ( GRET. Inc. ) Donations

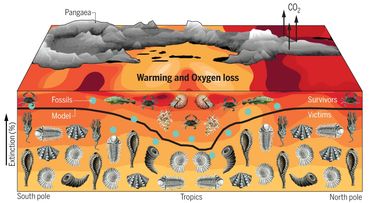

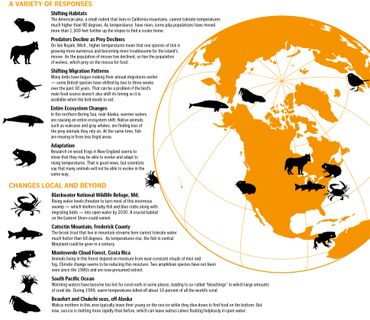

Environmental degradation due to the various forms of waste is at an all-time high. Liquid waste, organic waste, hazardous waste, recyclable rubbish, and municipal solid waste, these forms of waste contribute a great deal to damaging our environment. However, some waste can be recycled while the rest can be managed and disposed of in an environmentally friendly manner. Here at GRET, Inc., we specialize in the management and treatment of MSW through the utilization of advanced thermal Plasma Arc Gasification technology, increasingly viewed as the best suitable and economically viable approach for the management of waste(s).

The major advantages of [ Plasma Arc ] technology are:

1. Compared to combustion/incineration technology, it creates much less

atmospheric pollution.

2. In techno-economic terms, oxides of nitrogen and sulfur are not emitted during normal operations because the system works in the absence of oxygen.

3. Toxic materials become encapsulated and are therefore much safer to handle

than the toxic ash left by combustion/gasified processes.

Managing domestic, industrial, and commercial waste has traditionally consisted of collection, followed by disposal. Depending upon the type of waste and the area, a

level of processing may follow collection. This processing may be to reduce the hazard of the waste, recover material for recycling, produce energy from the waste or reduce it in volume for more efficient disposal.

Generation of Syngas through Plasma Gasification - Ideal for the treatment of the following listed waste streams:

Carbonaceous Waste:

Plastic waste

Hospital waste

Municipal solid waste

Wood and paper waste

Organic waste

Oil sludge and tar

Coal fines

Hotel waste

Global Renewable Energy Technologies, Inc. ' A Waste To Energy Non-profit Entity '

GRET ' WASTE-TO-ENERGY BENEFIT '

Complete destruction of Municipal Solid Waste, Toxic Waste, Toxic Gases, Nuclear Waste, Plastics, Tires, Batteries, Carcinogens,…The list goes on!

Here are other ' daily ' benefits from the P.A.R. process:

Fresh Clean Drinking Water:

A product derived from this extreme process.

Water generated from 2,000 tons of Processed MSW is about 70 Gal per ton that's about 140,000 gallons of purified water per day.

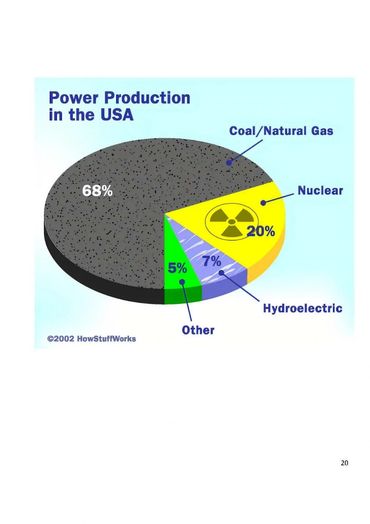

Electricity:

The electricity generated from 2,000 Tons of MSW is about 1,800,000 Kilowatt Hrs,… that's 66,000 plus homes that can be powered a day.

Slag:

This by-product can be used for construction backfill and road aggregate. About 320 tons of AG a day. Absolutely nothing is wasted in the P.A.R. process!

Many other daily renewable by-products can be derived from this [ Plasma Arc Recycling ] process… reintroduced into the market for replenishment and consumption….

All a result of Plasma Arc Recycling!

Customers have questions, AND we have answers... ask GRET, Inc.!

The GRET, Inc. Board of Directors is comprised of a group of

highly talented contractors and professionals dedicated to one

objective...saving the environment!

Plasma Gasification Technology

Plasma gasification technology is particularly suitable for the

disposal of hazardous and radioactive wastes.

Seen as an attractive option for the disposal of Municipal Solid Wastes.

This technology has the edge over the other processes involving

combustion as it can turn Municipal Solid Waste ( MSW) (organic

as well as inorganic) into a clean, green, renewable fuel in the

form of synthesis gas (Syngas) with almost no residues that

require further disposal.

PLEASE DONATE TO HELP !!!

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=7YE7K5NL2M4R4&source=url

GoFundMe ( GRET. Inc. ) Donations

Statistically speaking…

According to the Georgia Institute of Technology and Dr. Louis J. Circeo, Ph.D.…….

“ Plasma gasification can create more ' renewable energy ' than the

projected energy from solar, wind, landfill gas, and geothermal

combined…. with the potential to produce up to more than 5% of the

country's electricity needs " …….

Sincerely,

Rick L. Taylor I

Global Renewable Energy

Technologies, Inc.

" Converting Waste To Energy….

Now You're In The Solution "

Our GRET, Inc. Marketing Analysis: Unlimited Industry Growth & Unlimited Market Span:

The number of nations who might be interested in purchasing our template, products, and/or services each year is unlimited worldwide.

Due to the nature of the science and the nonprofit status of the organization, our relevant market span is the [ total annual revenues ] that our nonprofit could attain if we owned 100% of market control.

Science Overview:

What is Plasma Arc Gasification? Plasma Arc Gasification is a high-temperature Pyrolysis Process whereby the organics of waste solids (carbon-based materials) are converted into SYNGAS and inorganic materials and minerals of the waste solids produce a rocklike glassy by-product called vitrified slag. The high temperature during the process is created by an electric arc in a torch whereby gas is converted into plasma.

The process containing a reactor with a plasma torch processing organics of waste solids (carbon-based materials) is called plasma arc gasification.

The Plasma Arc Gasification reactor is typically operated between 7,200° and 12,600° F. The inorganic minerals of the waste solids (MSW) produce a rocklike by-product. Since operating conditions are very high (7,200°–12,600° F), these minerals are converted into vitrified slag typically comprising metals and silica glass.

This vitrified slag is basically none leaching and exceeds EPA standards. Metals can be recovered from the slag and the slag can be used to produce other by-products such as rock wool, floor tiles, roof tiles, insulation, and landscaping blocks, to mention a few.

The vitrified slag, being environmentally acceptable as a recyclable by-product, is one of the more positive attributes of the plasma arc gasification process for the management of MSW.

Our Mission:

§ To reduce the dependency on landfill disposal by managing and processing Municipal Solid Waste (MSW) and Hospital Medical Waste, converting them into ' renewable energy ' and consumer by-products for re-introduction into the consumer market(s).

§ To recycle the by-product for commercial, residential, and industrial usage.

§ To create MULTIPLE job opportunities.

§ To provide a safe environment for the personnel providing reliable systems.

Our Vision:

§ To provide a viable alternative solution for municipal solid waste,

§ To collaborate with municipalities to create immediate awareness for managing

waste with a sustainable process.

§ To stop the destruction of soil utilized for landfills – making a difference one step at a time.

Our Objectives:

• To assess the potential for other waste material other than municipal solid waste in the region

as supplemental plant feedstock.

• To assess potential markets for the plasma plant by-products.

• To determine the feasibility, requirements, and costs of an interconnect with the

power utility grid.

• To assess the option that the local industries could potentially be the exclusive power customer for the Plant.

• To develop a Pro-forma model so that various options can be evaluated for the Plant capacity and material and energy output configurations over an assumed initial 20-year contract operating phase which... Includes:

• Production of SYNGAS for conversion to electrical power.

• Production of SYNGAS for direct use and conversion to fuel products.

• Production of insulation from slag to enhance project revenues.

• Determining the potential economic impact of the Plant on the region.

§ GRET’s intendant customers are local municipalities, industry, and hospitals.

Global Renewable Energy Technology, Inc.

VALUE-ADDED SERVICE CAPABILITIES:

Green Waste:

• Tipping/Dump fees $45/ton x 2,000 tons = $90,000.00 USD/day.

Stream Produced:

• Jet Fuel

Carbon Credits:

Compliance” carbon offset programs (run by governmental bodies in California).

The label used for offset credits:

Air Resources Board Offset Credit

(ARBOC) Voluntary” International carbon offset programs (run by NGOs)

• The Gold Standard: Verified Emission Reduction (VER)

• Plan Vivo: Plan Vivo Certificate (PVC)

• The Verified Carbon Standard: Certified Carbon Unit (VCU)

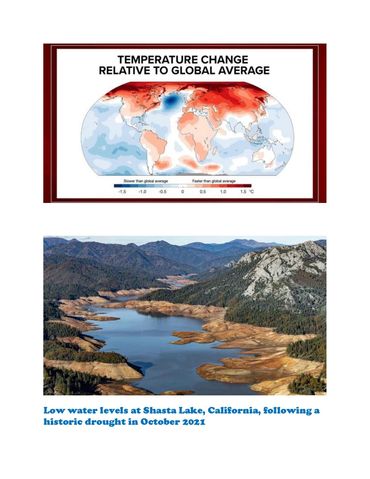

Global Renewable Energy Technologies, Inc. is on a ' never-ending quest ' to do all that we can to ensure that the

environment survives the ' abuse and misuse ' that is inflicted upon it every day, every month,.. every year!

We MUST end this trend and take ' better care ' of the world we

live in ...... before the crisis becomes irreversible!

" NOW YOU'RE IN THE SOLUTION! " (tm)

“ GRET, INC. MISSION STATEMENT... ”

Our mission is to deliver an efficient, environmentally responsible

the solution to convert waste - to - energy through enhanced and

the advanced technology of Plasma Arc Processing.

Our waste-to-energy projects will provide a ' global solution ' to our waste and Greenhouse Gas Emissions problem while producing safe, renewable energy for redistribution and service via Plasma Arc Recycling.

Environmentally Concerned,

Rick L Taylor I,

Director - Business Research Development

Global Renewable Energy Technologies, Inc.

( Field Ph. # )( 714 ) 873 - 5582

Corp. Email: gretincorp@gmail.com

“ Converting Waste To Energy...

Now You're In The Solution” (tm)

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=7YE7K5NL2M4R4&source=url

GoFundMe ( GRET. Inc. ) Donations

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

" WELCOME TO THE WORLD OF GLOBAL RENEWABLE ENERGY TECHNOLOGIES, INC. "

' YOUR WASTE-TO-ENERGY SPECIALISTS '

( Global Renewable Energy Technologies, Inc. )

In closing,… being a Not-For-Profit corporation puts GRET, Inc. in a unique and potentially fortuitous position,...

[ WE ] don't answer to profit... nor to the ' BIG ' "profit machine "!

[ WE ] REINVEST TO EXPAND OUR SERVICES TO THE PUBLIC...

[ WE ] DONATE OUR PROFIT TO WORTHY CAUSES... CHARITABLE AGENCIES AND OTHER 501(C)(3) ORGANIZATIONS HELPING THE HOMELESS, POOR, AND THE ELDERLY...

[ AND ]... BECAUSE IT'S THE RIGHT THING TO DO ...

[ WE ] ... DO THE RIGHT THING !!!

" CONVERTING WASTE TO ENERGY... NOW YOU'RE IN THE SOLUTION! " (tm)

We have the opportunity - with your help and assistance - to bypass the ' only for profit ' HUGE companies who " know " that the time is now, but refuse to move in the " right direction " to resolve the [ GHG ] emissions problems that are creating Global Warming, continuing ' status quo ' conventional landfill burials. Plasma Arc Processing is OUR FUTURE OF SAFE WASTE MANAGEMENT TODAY!

We must find, create, or develop a " new way " of approaching life today ... through technology, yes... but, mainly through the ' selfless ' acts of people who will step up unreservedly, and ultimately make a difference in how we live... tomorrow, the next,... and future years to come!

PLEASE WATCH THIS " IMPORTANT " YOUTUBE PRESENTATION: https://www.youtube.com/watch?v=JZmqxfpvzf4

GoFundMe ( GRET. Inc. ) Donations

https://www.gofundme.com/f/help-gret-build-a-coachella-ca-wastetoenergy-facility?qid=bb914f3f18577d24addf977a8200be7b

Again, thank you in advance for your kind consideration, and as an ' SBA Certified Micro Small Business ', we look forward to your approval and support.

Respectfully Submitted,

Rick L. Taylor I, Director - Business Research Development

( 714 ) 873 - 5582

gretincorp@gmail.com ( Corp. Email Address ]

greticorp.org [ Corp. Website Address ]

We would love the opportunity to serve the public with the highest level of support, experience, and service...

Thank You In Advance!

GRET, Inc.

( Global Renewable Energy Technologies, Inc. )

" PLEASE HELP US... HELP ALL ! "... DONATE TODAY !

https://www.paypal.com/cgi-bin/webscr?cmd=_s-xclick&hosted_button_id=7YE7K5NL2M4R4&source=url

GoFundMe ( GRET. Inc. ) Donations

68390 Durango Rd., Cathedral City, California 92234-3698, United States

§ Ph. # ( 714 ) 873 - 5582 - Rick Taylor, Director - Bus./Mktg. § Ph. # ( 213 ) 308 - 8255 - Michael Castro, Exec. Director § Ph. # ( 310 ) 308 - 8222 - John Apoian, Director § Ph. # ( 760 ) 831 - 3868 - Joe Velasquez, Director

Today | Closed |

§ Global Renewable Energy Technologies, Inc.

29125 SHORECLIFF COURT, LAKE ELSINORE CA 92530-7283

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.